Electrically Operated Butterfly Valves: Leading Manufacturers and Suppliers in India - Concorde Valves & Automations

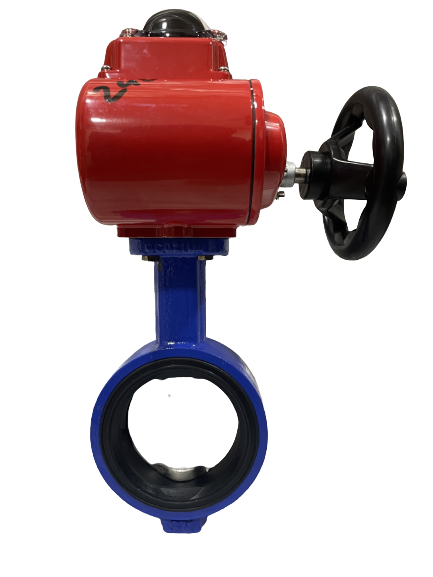

As a leading manufacturer and supplier in India, Concorde Valves & Automations specializes in delivering high-performance, electrically operated butterfly valves renowned for compact design, reliability, and efficiency. Our butterfly valves with electric actuators provide precise flow control for water treatment, HVAC, and oil & gas processing.

What Are Electrically Operated Butterfly Valves?

Electrically operated butterfly valves are compact valves that control liquids, gases, and slurries using an electric actuator. The actuator’s motor drives the stem to rotate a disc 90 degrees to open or close the valve. When the disc is parallel to flow the valve is fully open; perpendicular and it’s closed. These valves are popular for remote, precise control in automated systems and offer faster, more reliable operation than manual or purely pneumatic setups.

Benefits of Electric Actuated Butterfly Valves

- Compact and lightweight: High output torque in a small footprint.

- Remote operation: Electric actuators for butterfly valves enable safe control in hard-to-reach locations.

- Quick and reliable: Fast response for on/off service and modulating control.

- Durable and low maintenance: Built for long service with minimal upkeep.

Key Features of Electric Butterfly Valves

We provide a diverse range of electric actuated butterfly valves to meet industry needs:

- High durability: Robust CI, ductile iron, and stainless steel options for harsh environments.

- Multiple sizes & configurations: 40 mm to 600 mm to match flow and installation needs.

- Versatile operation modes: Hand lever, worm gearbox, pneumatic, and electrical actuation.

- Wide pressure range: PN10, PN16, ANSI 150 and more.

Detailed Product Specifications

| Valve Size | 40MM TO 600MM |

| Media Compatibility | Water, Air, Gas |

| Pressure Rating | PN 10 & PN 16 |

| Body Material | Cast Iron (CI), Stainless Steel (SS304, SS316), Ductile Iron |

| Disc Material | CF8, CF8M, CF3M, SG Iron, Teflon Coated, Powder Coated, Rubber Lined |

| Seat Material | EPDM, Nitrile, Viton, Hypalon |

| Shaft Material | AISI 410, CF8, CF8M |

| Operation Type | Hand Lever, Worm Gear, Pneumatic, Electrical Actuated |

| End Connection | Wafer, Lug, Flanged |

| Temperature Range | -25℃ to 130℃ (Soft Seating), -25℃ to 600℃ (Metal to Metal Seating) |

| Protection Class | IP65, IP67, IP68 |

| Standards Compliance | API 609, ISO 5211, EN 593 |

High-Performance Electric Butterfly Valves

Concorde Valves & Automations also offers high-performance electric butterfly valves for large flows and moderate pressure drops. Options include double-eccentric discs, PTFE or metal seals for tight shutoff, and reduced operating torque. Suitable for oil & gas, chemical processing, and power generation.

| Size Range | 1.5" to 48" |

| Construction Type | Double Eccentric Disc Design |

| Body Material | WCB, CF8, CF8M |

| Disc Material | WCB, CF8, CF8M |

| Seat Material | PTFE (Metal to Metal on request) |

| Operating Temperature Range | -25℃ to 180℃ (Soft Seating), -25℃ to 600℃ (Metal to Metal Seating) |

| Pressure Rating | ANSI 150 Class, ANSI 300 Class |

| End Connection | Wafer, Lug, Flanged |

| Operation Modes | Hand Lever, Worm Gear, Pneumatic, Electric Actuated |

Applications of Electrically Operated Butterfly Valves

Our electrically operated butterfly valves are widely used in:

- Water & Wastewater: Control of water, chemicals, and sludge in treatment plants.

- HVAC: Efficient regulation of heating, ventilation, and air conditioning loops.

- Oil & Gas: Reliable isolation and control in pipelines and refineries.

- Chemical Processing: Safe handling of corrosive media with precise control.

- Food & Beverage: Hygienic, efficient flow control in production lines.

Why Choose Concorde Valves & Automations?

We deliver top-quality electric butterfly valves to international standards with advanced manufacturing, rigorous QC, and responsive support.

- Extensive inventory: Ready stock for faster turnaround.

- Customized solutions: Tailored sizing, seating, and actuation.

- After-sales support: Installation guidance, maintenance, and service.